At present,most of concrete mixing plants cannot provide good residual concrete recovery system in our country. The majority adopt the sedimentation pond to complete the separation of liquid and solid. Although this method can realize part of sewage recycling, it cannot solve the recycling problem of sand stone and cement in the concrete thoroughly.

During the production concrete, some scrap concrete may be generated. Once these scrap concrete coagulates, it will pollute environment. According to statistics, scrap concrete composition accounts for 1%-2.5% of the total concrete production, which brings massive economic loss and the environmental pollution. In order to meet the market development and demand, combined with our long years` experience in research and manufacturing the aggregate processing equipment, we have developed a new generation scrap concrete recycling system, CRP series concrete cycling plants achieves truly zero emission.

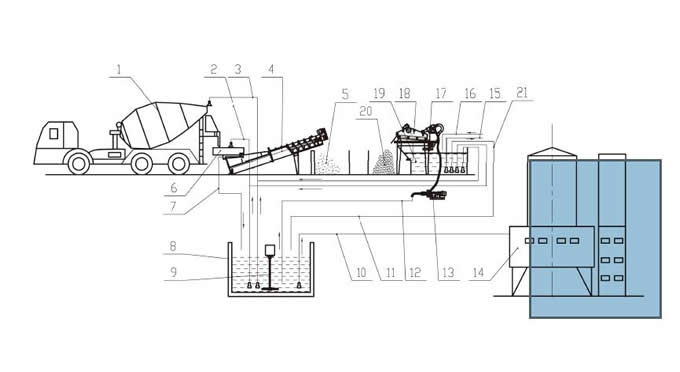

Work Principle:TCRP series concrete recycling plants are composed of sand washer,water circulation and control system etc.

Working process:

Agitating lorry pours the scrap concrete into discharge mouth.Under the rotation of the screw,the sand and stone tumbles and rubs mutually to remove the impurity covering on the surface of the aggregate.Simultaneously it destroys the hydrosphere of the aggregate. The sand and stone can be delivered into the discharge hole after rotation. Then all the material enters into the aggregate recycling pile, at the same time completes the cleaning function. After cleaning and screening, the aggregate can be recycled using(vibrating screen is optional part).

Water cycling system (water supply system):

Water cycling system is composed of the pump ,mixer, limit device and water supplying pipe etc.

The main function: 1.add water into the concrete truck mixer; 2. it cleans the feeding parts, the sand washer and separates the aggregate. The water is sedimentary water from the above process of the system or the running water supplied by outside .

Control system:

The central control cabinet realizes all function of the concrete recycling plant. The support of cleaning aggregate is fixed on the top of the feeding device. It is equipped with the limit device and water supplying pipes which supplies the water to concrete mixer. This is done under the control of electrics system.

Advantages and Features :

Advantages and Features : [1] simple and compact structure,convenient operation and maintenance;

[2] ecycling aggregate continuously;

[3] avoiding the environment pollution from concrete and enhancing economic benefits of the concrete manufacturer for aggregate recycling.

Technical specification:| Model | CRP610 | CRP762 | CRP914 |

| Screw diameter(mm) | 610 | 762 | 914 |

| Max feed size(mm) | ≤50mm | ≤50mm | ≤50mm |

| Power(KW) | 5.5 | 11 | 15 |

| Capacity(t/h) | <20 | 20-30 | 30-50 |

| Rotation speed of screw | 32 | 26 | 20 |

| Recycling water consumption | 10-15 | 10-15 | 10-15 |