Stone processing product line is composed of feeder, jaw crusher, impact crusher or cone crusher, vibrating screen and vertical shaft impact crusher ect. Supported by the belt conveyor it is a whole processing line for stone producing. Various kinds of materials can be used for aggregate and manufactured sand such as hard limestone, granite, basalt, river gravel and metallurgical slag ect. It is applicable for hydroelectric industry, building material, highway and city conctruction ect. YIFAN designs best flow chart with various configuration of equipments to meet the different requirements of customers. This plant is high efficiency,low cost, big processing capacity ect.

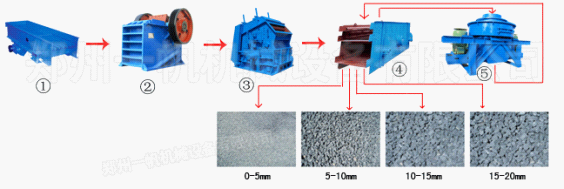

Process flow of stone product line:

Vibrating feeders feed material into jaw crusher for primary crushing. Then material goes into impact crusher or cone crusher for secondary crushing after get reasonable size from primary jaw crusher. And then finished materials goes to vibrating screen for gradation. Satisfactory material is transported by conveyor belt. Output sizes is determined by model of crusher and vibrating screen.

Features and Advantages:[1] High degree of automation;

[2] Low operation cost with high rate of crushing;

[3]High Capacity with low pollution;

[4]Easy maintainence;

[5]Finished material with epigranular size and good shape meet the national standard of building material. It is epigranular and good shape.

The configuration of equipments of stone production line is mainly based on customers requirements on dimension of finished material, capacity and the purpose of finished material. SHANDE provides presale, midsale and aftersale services for customers. We devote ourselves to design the most reasonal and economical flow chart for you.