SMH series hydraulic cone crusher adopting world advanced technology is designed and made through to be the crusher of world advanced level. it is widely used in metallurgical, architectural, water and electricity, traffic, chemical, architectural material industries. It is suitable for crushing varies of mid hard and above mid hard ores and rocks.

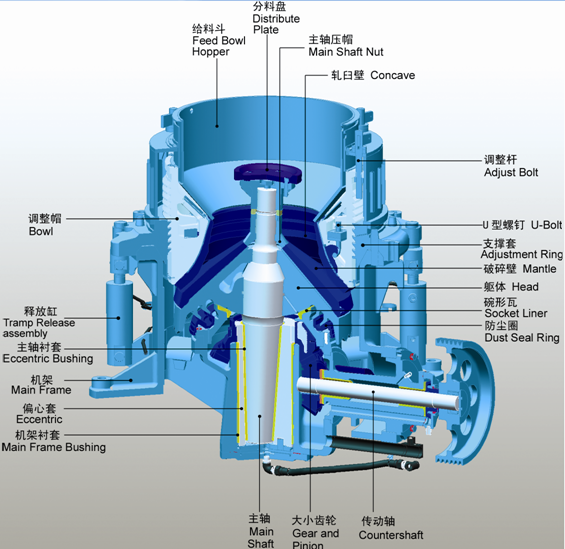

Working principle:The machine is composed of main frame, countershaft, eccentric shaft, socket bearing, crushing head, adjust device, bowl and so on. When the crusher works, the electric motor revolves eccentric shaft by horizontal shaft and a couple of bear gear. The axle centre line do the rotary oscillation, this make the surface of mantle sometimes close the surface of concave ,but sometimes leave, thereupon the mineral is ceaselessly squeezed and circles to crush in the crushing chamber.

[1] Reasonable structure advanced crushing principle and technical specification, reliable work and low cost.

[2] Strong crushing ability; High efficient productivity; High capacity.

[3] Reliable Hydraulic system providing safe and effective overload protection.

[4] types of crushing chamber are for wide range of product size requirement.

[5] High automation adopting hydraulic adjustment and hydraulic clean cavity setting.

Main Technical Parameter:

Note: Capacity is total tons per hour passing through crusher at open circuit when density of feeding is 1.6x103 kg/m3. Capacities are relative to physics character and type of feeding, feeding size and composition and so on.